High precision tungsten carbide CR

The newest super wearable tungsten coating techniques and the machining of the corrugated rolls help customers to achieve lower paper waste, higher running efficiency and better economic productions. The life span of the tungsten carbide corrugated rolls is 3-5 times longer than the hard chrome corrugated rolls, which reduces about 65-80% changing of corrugated rolls, also helps to avoid the frequent loss of changing spare parts due to the wearing and tearing of corrugated rolls.

Technical figures of tungsten carbide CR

- Special 48CrMo alloy steel fine forge for corrugated roll

- Hardness of base unit after mid frequency quenching ≥ HRC 58

- Coating hardness >HV 1250-1400

- Combination hardness > 75MPa

- Porosity <1%

- Optimizing design for economical profile

- Precise grinding and polishing gear surface, roughness Ra ≤ 0.5μm

Tungsten coating techniques

- The most advanced equipment in the world

- Modern high-tech coating material product

- Advanced professional thermal spray technology

- Unique high precision polishing techniques

Longer total life

Longer linear meters/time

Higher paper board quality

Lower spare parts loss

Lower production cost

Lower consumption cost

The technical advantages of Peripheral heating CR

- Higher heating efficiency

- More even temperature distribution

- More even glue application

- Lower requirements for steam pressure

- No ‘banana effect’ while idling

- Reducing the pre-heating time

- Save steam usage

Boli CR excellent flute design

Boli can adjust the flute design base on customer requirements under the support of BHS and make professional new customized flute design for corrugated roll.

We better our precise flute design through a professional software to comprehensively consider factors of pitch, paper board hardness and, thus to help customer to achieve production with low gsm paper usage.

Flute

Number

Height

K

26±2

5.5~6.5

A

34±3

4.5~5.0

C

41±3

3.5~4.0

CB

45±3

3.0~3.5

B

50±4

2.5~3.0

BE

66±3

1.9~2.1

E

93±6

1.1~2.0

F

136±20

0.6~0.9

G

185±12

0.5~0.65

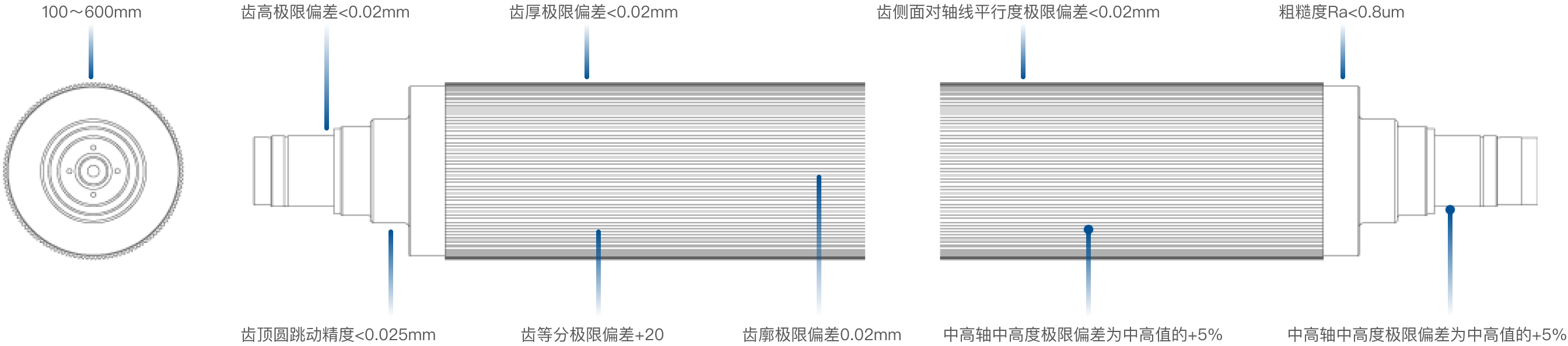

Specification and accuracy index of Boli corrugated roll

Corrugated roll production in 39 processes

Equipment and Techniques

- An over 6000 m2 workshop

- The most advanced automatic CNC precision corrugated roller grinder

- American JP8000 supersonic flame thermal spray machine for tungsten carbide corrugating rolls

- Only CNC chrome plating machine in China

- First and only Germany imported ZEISS three coordinate measuring platform for the quality checking of corrugating rolls in China

- CNC controlled mid frequency quenching and automatic welding equipment

- World class advanced 5 meters CNC machining center

Powered by BHS

BHS offers full support to Boli Corrugated rolls comprehensively via technicality, production, quality control, after sales services, etc

Technicality

Production

Quality control

After sales services

Show details

Drag and drop images for full view